BEAMIT and the InShaPe Project: Boosting Productivity and Unlocking New Horizons in Additive Manufacturing

Authors: Federico Uriati (Beamit), Michele Caldarini (Beamit), Robin Prudlik (Oerlikon)

Additive Manufacturing (AM) is experiencing rapid evolution, and the European InShaPe project is a concrete example of this progress.

BEAMIT, as a leading player in the sector, has played a key role in demonstrating the success of integrating beam shaping into the LPBF process.

An industrial gas turbine swirler was selected as a critical component, specifically designed to optimize the mixing of fuel and air, improve combustion, and reduce emissions. Its complex geometry and the requirement to withstand high temperatures and mechanical loads make it an ideal test case for additive manufacturing – featuring shapes that are unachievable using conventional methods. Early trials on this application were conducted at the TUM Garching facility using a beta prototype system equipped with a 2 kW laser and advanced beam shaping capabilities.

This preliminary phase, as highlighted in the dedicated InShaPe blog post (Metal Additive Manufacturing – Adoption of Innovative Beam Shaping Technology for Greater Efficiency and Sustainability), focused on testing different beam profiles and process conditions to maximize productivity and ensure the manufacturability of complex geometries like the swirler. The research provided valuable insights into process stability and performance, laying the groundwork for the full-scale testing that followed.

Maximizing Productivity with Beam Shaping

One of BEAMIT’s most striking achievements was the significant increase in productivity made possible by integrating beam shaping into the LPBF process. By developing optimized process parameters, BEAMIT achieved a build rate of 86.4 cm³/h, representing a 5.7x increase compared to the standard Gaussian beam at 40 µm layer thickness.

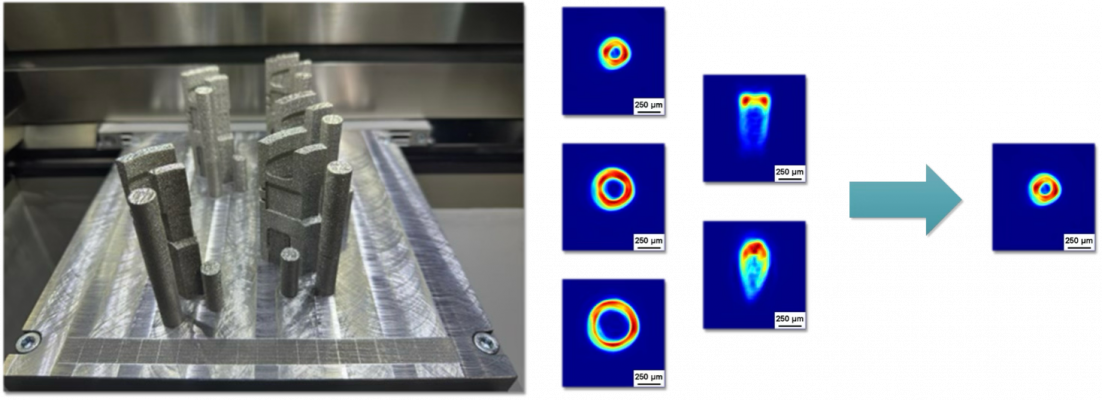

This productivity gain was achieved without compromising material quality, with tests confirming a material density exceeding 99.8%, indicating high internal quality and process reliability.

The remarkable results achieved in InShaPe were the outcome of intensive research and multiple iterations aimed at fine-tuning the beam shaping parameters.

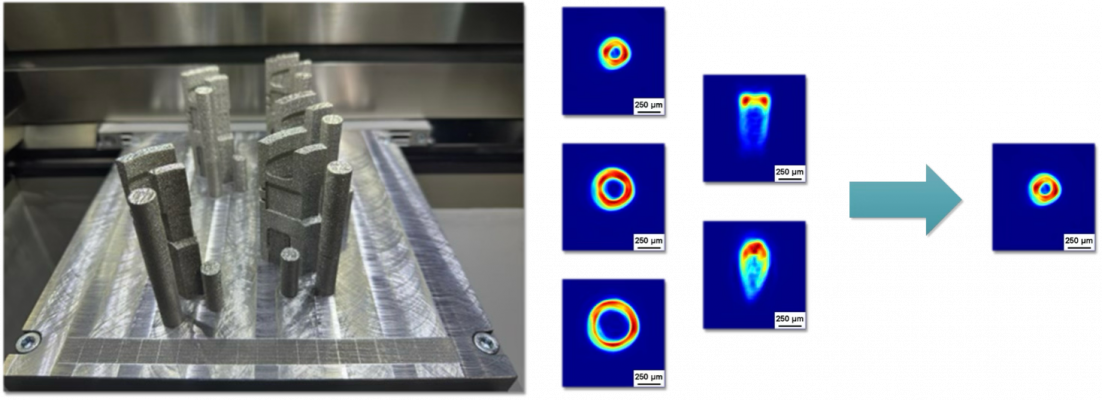

A wide range of configurations were tested, combining:

- Different beam shaping profiles, including ring, chair, and teardrop shapes, to modulate the energy distribution and improve melt pool stability.

- Variations in laser power (from 700 W to 1300 W), scanning speed (1200 to 3000 mm/s), and hatch spacing (0.1 to 0.15 mm) to balance deposition rate with material integrity.

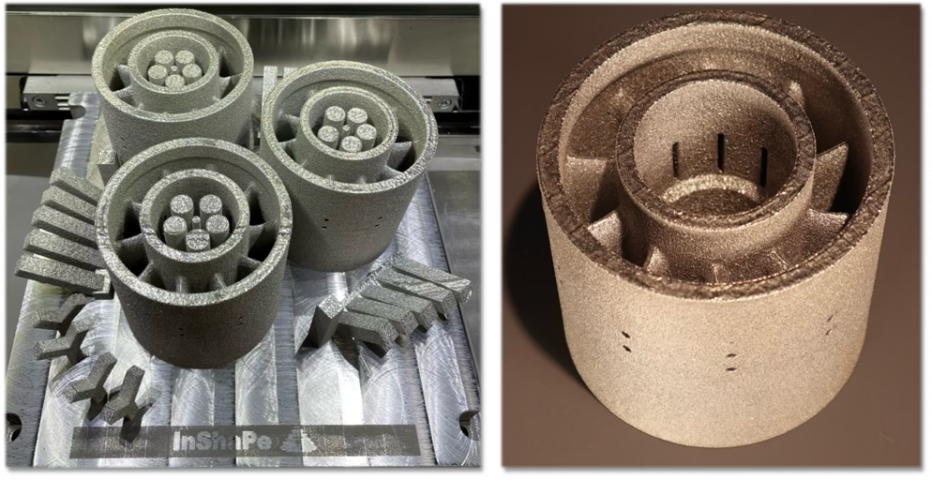

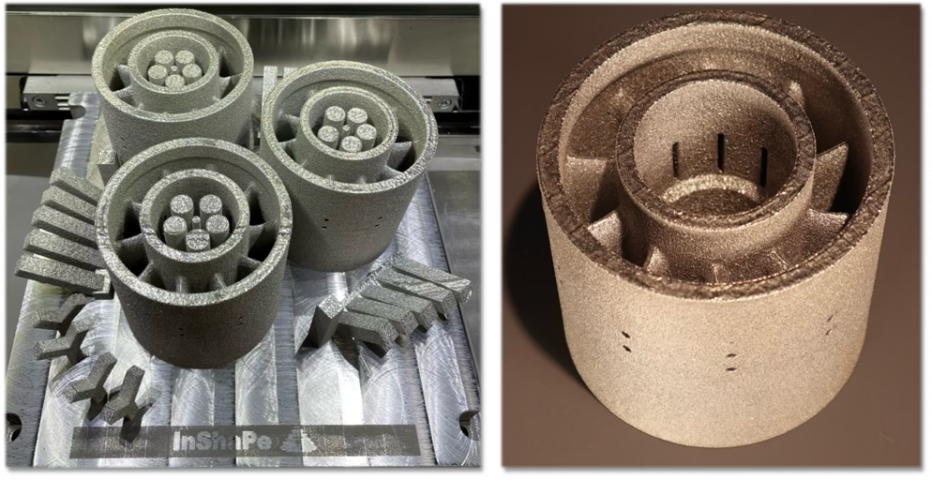

Figure 1 – Image of a build job produced with innovative beam shaping system and differenti beam shapes applied to coupon and sections of the final use case part. Images: BEAMIT

Each iteration was followed by comprehensive analyses, including:

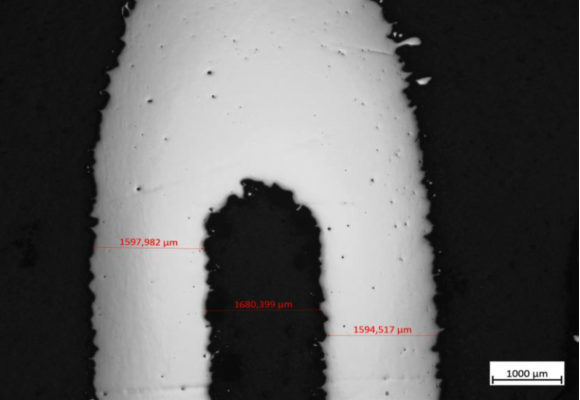

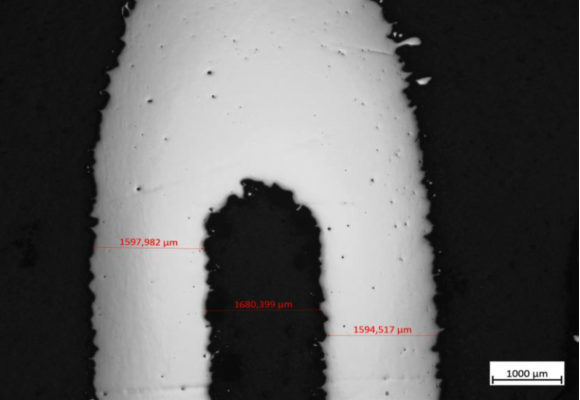

- Density evaluation

Figure 2 – Relative density image of In718 produced with beam-shaping system Images: BEAMIT

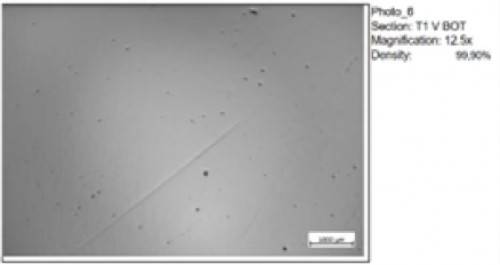

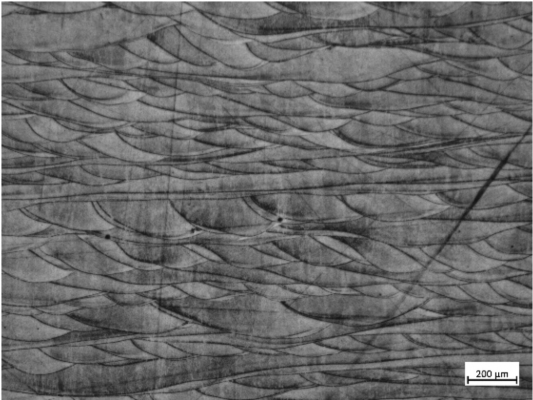

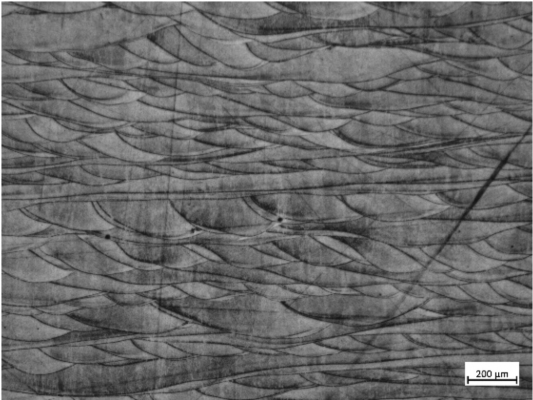

- Metallographic inspections, examining the microstructure at multiple heights (top, mid, bottom) and orientations (horizontal, vertical).

Figure 3 – Metallographic image of In718 produced with beam-shaping system and section of swirler produced with Innovative technology Images: BEAMIT

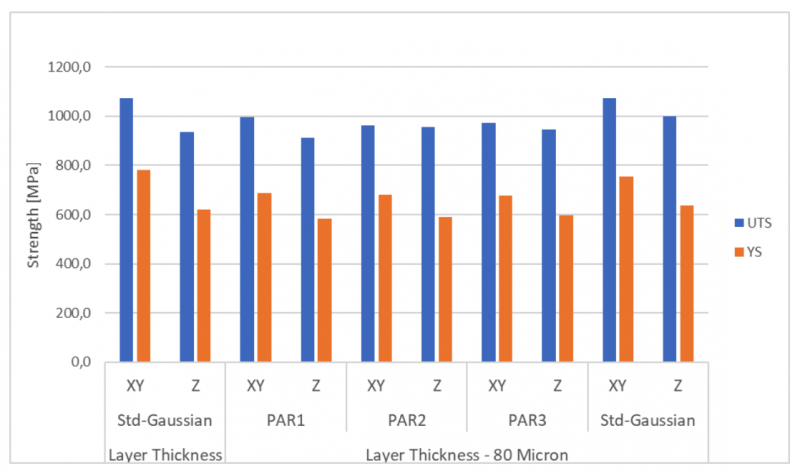

- Mechanical testing of both horizontal and vertical samples.

Figure 4 – Final comparison of yield and tensile strength between process parameters developed in InShaPe and state-of-the-art parameters (BEAMIT). Images: BEAMIT

These findings were validated through full-scale component builds, including complete swirler parts, confirming the reliability of the selected beam shaping parameters for complex geometries.

Additional iterations will be necessary to fully qualify the part and its geometry. Research on beam shaping will continue to focus on enhancing part quality and surface finish, with ongoing optimization in the subsequent phases of the research project.

Figure 5 – Build job with three full swirler produced with innovative beam shaping system with optimized process parameters selected as best in term of productivity and material quality. Images: BEAMIT

Thermal Treatments: Strength and Reliability

In parallel, BEAMIT conducted extensive research into advanced post-process heat treatments aimed at enhancing mechanical performance. A comprehensive evaluation was carried out, systematically testing combinations of stress relief, Hot Isostatic Pressing (HIP), solution treatment, and aging. This integrated approach – combining optimized process parameters with precisely tailored heat treatments – paved the way for reliable, high-quality production of complex AM components.

The importance of this research is underscored by the inherent properties of Inconel 718 (IN718), which requires heat treatment to achieve its final metallurgical structure and mechanical performance. Recognizing this, BEAMIT partnered with IMT to carry out an in-depth characterization campaign, with the findings to be published soon in a dedicated research paper. The insights gained from this research are highly valuable, as they establish the optimal heat treatment sequence to achieve superior mechanical properties, while also boosting productivity and reducing lead times by streamlining the entire value chain.

The results could also provide key insights into how heat treatments can be further fine-tuned and optimized specifically for materials produced using beam shaping technology.

A Strategic Vision for the Future

The InShaPe project has proven the potential of beam shaping in additive manufacturing, boosting productivity and process efficiency.

The future of AM lies in innovative approaches like beam shaping, breaking down long-standing barriers and bringing additive manufacturing ever closer to the demands of the most advanced industries.